Hard water contains an excess of minerals such as calcium, magnesium, manganese, and iron that can be an expensive nuisance as far as operation and maintenance costs are considered.

Water Softening is an important process which removes hardness components of water. When water is hard it can clog pipes and soap will dissolve in it less easily. Hard water causes a higher risk of limescale deposits in all cold and hot water systems. This increases the cost of domestic water heating by up to 15-20%. Hard water has a damaging effect on household and industrial machinery, such as laundry machines, solar & thermal heaters, boilers, cooling towers etc.

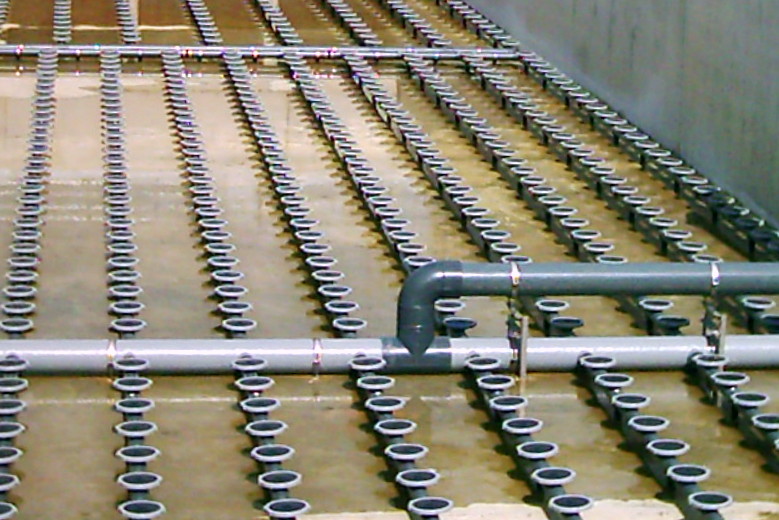

In the water softening process, the water supply passes through the water softener over resin beds, rows of resin beads perform an ion-exchange operation. The resin beads chemically attract the unwanted ‘hard’ mineral ions and exchange them with sodium ions. The softener resin is usually a strong-acid cation resin.

Softeners mainly remove Calcium (Ca2+) and Magnesium (Mg2+) ions. Calcium and Magnesium are often referred to as ‘hardness causing minerals’.

When the resin beds become saturated with the minerals, the water softener flushes them out with a regenerant solution and the process begins again. Water softeners are fairly easy to operate and maintain. Softeners can operate automatically, semi-automatically, or manually.

Capacity of Each softener is rated on the amount of hardness it can remove before regeneration is necessary.

Kanku Kenya is one of the leading water softener manufactures in Kenya. Capacities of Softeners are designed for various flowrates of treatment. It ranges from small compact units of flowrate 1m3/hr to larger ones of flowrate 50m3/hr. Fiber Reinforced Plastic (FRP) vessels, plastic or stainless steel flow pipes and long lasting multiport valve are utilized for easy operation and control.

Custom-built Design and Installation setup can also be delivered.